SAVE 50%

SAVE 50%

STOCK POUCHES & BAGS

Shelf-ready pouches that look premium & sell faster

Stock pouches ready to ship today. Samples available.

- Food-safe materials

- Samples available

- Ready to ship today

Shop by pouch type

Pouch types & formats

Food-safe, shelf-ready options delivered fast.

- Stand Up Pouches

- Coffee Bags

- Flat Bottom Bags

- Kraft Paper Pouches

- Jar- Shaped Pouches

- Retort Pouches

- Spout Pouches

Stand Up Pouches

ShopThe Best Stand Up Pouches For Your Products Are Right Here Stand up pouches are convenient, resealable packaging bags that can stand on their own when filled. If you’re looking ...

Coffee Bags

ShopCoffee Packaging How you package your coffee brand really makes all the difference. It affects the response you get from customers, the products’ ability to seal in the flavour ...

Flat Bottom Bags

ShopFLAT BOTTOM POUCHES Flat bottom bags are a popular choice for a range of industries because they combine the best characteristics of stand up pouches, gusset bags, and cardboar...

Kraft Paper Pouches

ShopOur Kraft Paper Packaging Options There are many benefits to using kraft paper packaging. Its durability and physical protection barriers have led to its widespread use in the ...

Jar- Shaped Pouches

ShopJar Shaped Pouch Packaging For a fun a quirky spin on traditional pouch packaging, try one of our jar pouches!

Retort Pouches

ShopSpout Pouches

ShopSHOP

Pouches on sale

Discounted pouch styles, ready to ship.

WHY CUSTOM PACKAGING

Stand out with custom food packaging

Packaging is your first impression. In a crowded market, smart custom packaging helps your product work harder on-shelf.

Stand out when your product sits beside competitors.

High-barrier films lock in freshness and flavour, reducing waste.

Fill, seal and re-close with ease—faster packing, happier customers.

Unified formats and finishes protect brand integrity.

Pick the right format to cut freight, shelf and material waste.

Fast Australian production keeps projects moving.

FAQs

Custom packaging common questions

Quick answers about MOQs, finishes, formats, pricing and timelines for our Australian-made custom pouches.

Start custom packaging-

Why can’t I order less than 5,000 units?

Each stage of production requires machine setup, which makes very small runs expensive per unit. Our MOQ is 5,000 units—you can split across SKUs.

-

Why can digital print do matt or gloss, but not both?

Combination finishes require a selective matt varnish (traditional plate/cylinder printing). Digital runs on a matt or a gloss film for a full-pack finish.

-

Why can’t you make Flat Bottom or Spout Pouches?

These formats need specialised machinery and extra components fitted during bag-forming. Our current equipment isn’t configured for them.

-

What if I need to change my artwork?

Changes are fine up to final proof sign-off. Revisions may add time while we redo proofing and setup.

-

What is CMYK and how does it work?

CMYK = Cyan, Magenta, Yellow & Key (Black). Digital printing layers tiny dots of these inks (plus White where needed) to build up your artwork. Up close, any photo is a pattern of coloured dots — your eye blends them into full-colour images.

-

Can you print kraft paper pouches?

Yes — we now offer printed kraft paper packaging via our custom service. Talk to us about whether kraft works for your product.

-

How much does it cost?

Pricing depends on volume, size, features (zipper, hang hole, etc.) and material structure. Because every job is custom, we quote like most commercial print/manufacturing providers. The more detail you provide, the faster and more accurate your quote will be.

-

Do you have an in-house designer I can use?

We focus on production and don’t currently offer in-house artwork. We can recommend experienced packaging designers we work with regularly.

-

Why can’t you give an exact lead time when quoting?

Lead times depend on many factors: how quickly artwork is approved, print & lamination scheduling, bag-forming slots, and final QC. With multiple orders in the queue, timing can vary — but once artwork is signed off we can provide a reliable window.

-

Why does digital printing cost more per unit than gravure or flexo?

Traditional gravure/flexo presses run at very high speeds with higher MOQs, so setup cost is spread over more units — giving a lower unit price at scale. Digital inks/materials are comparatively dear (think home printer cartridges), and our goods are 100% Australian-made, so we don’t benefit from offshore labour rates.

-

I ordered 5,000 pouches but received ~4,950 — why?

A small production tolerance (under- or over-run) is normal due to:

- Machine setup and test material

- Items failing strict QC (e.g. early-run seal or print imperfections)

- Film supply variances

We aim to deliver as close as possible to the ordered quantity with minimal waste. -

Why can’t you colour-match Pantone like traditional print?

Plate/cylinder printing uses spot inks mixed to exact PMS recipes and applied in dedicated stations — perfect for precise matches. Digital uses CMYK (+ White) to simulate colours. New digital inks (Orange, Green, Violet) can get closer to PMS; let us know if you need these for your job.

From the blog

Stories, guides and behind-the-scenes from The Pouch Shop team.

View all articles

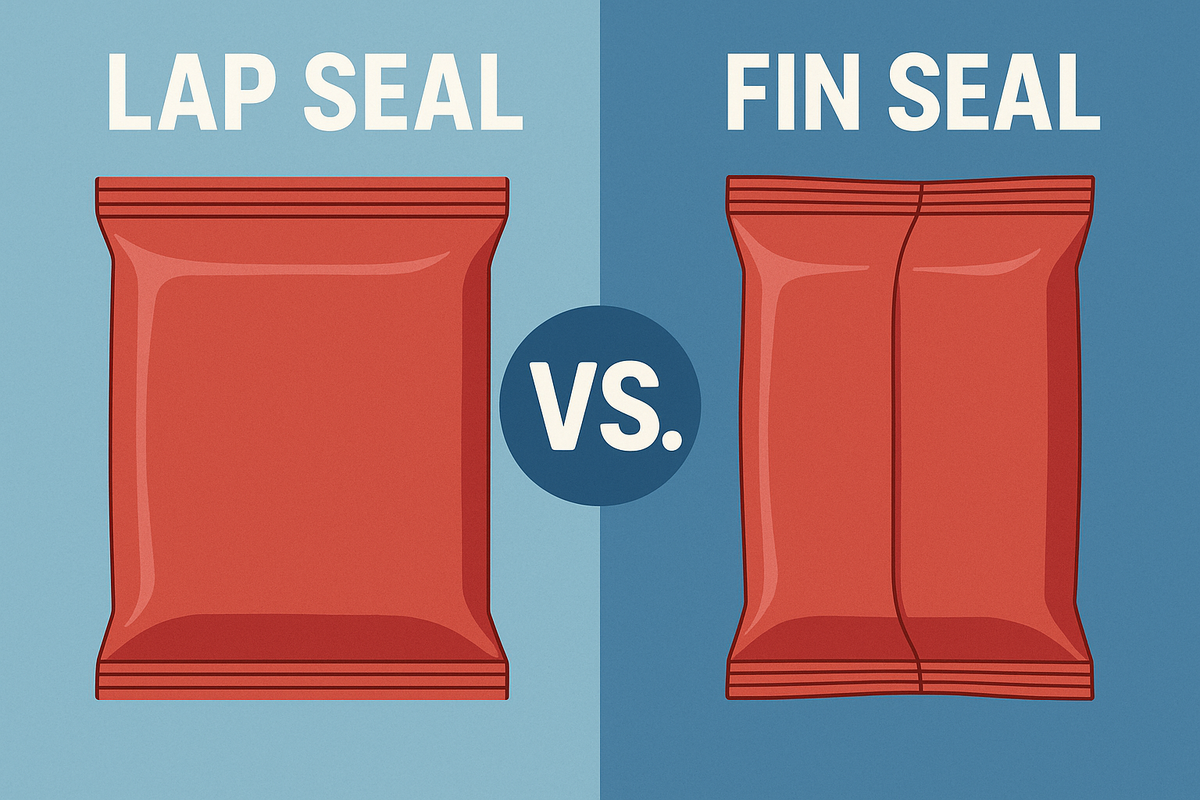

Lap Seal vs Fin Seal: What’s the Best for Your Pouch Packaging?

One key decision that often gets overlooked in designing packaging is choosing between a lap seal and a fin seal. Yes...

Read more

Understanding the Power of Packaging Design as a Marketing Medium

In the bustling aisles of a supermarket, your product competes for attention amidst a sea of competitors. It will qui...

Read more

Minimalist Packaging - Why Simplicity is More

The Beauty of Minimalist Packaging In a bustling supermarket, products often compete for attention with packaging t...

Read more

The Crucial Role Food Grade Packaging Plays

Over 5 million Australians are treated for food poisoning related issues each year. This has left consumers and regul...

Read more

Kava Packaging & Importation - What You Need To Know

What is Kava, Anyway? Kava (also known as Kava Kava) is a Pacific Island herb that means "bitter" in Tongan. It is p...

Read more

Qualities of A Pet Food Supplier You Can Trust

According to studies, what we feed our pets has a significant impact on their health and life span. Pet owners are be...

Read more